High-End D Type Keg Coupler Handbook – Home Brew Fundamentals

A full keg, or half-barrel keg, encompasses about 15.5 gallons of beer. That makes roughly 165 twelve-ounce servings. Such vast volume underscores the requirement for suitable dispensing instruments for quality draft beer. If you are committed to brewing or starting your home bar, knowing the D type keg coupler is crucial.

In the craft beer surge, selecting the optimal keg faucet is crucial for your brew’s crispness and palate. Both home brewers and pub owners realize that a premium keg coupler changes the beer dispensing experience. This guide will cover the key gear for first-rate draft beer service, pointing out places like Installation Parts Supply for a range of D type keg coupler.

Summary Points

- A full-size keg holds approximately 165 twelve-ounce portions of beer.

- The proper keg coupler is vital for maintaining beer quality.

- Selecting premium apparatus enhances the draft beer experience.

- Craft beer’s demand has escalated the requirement for home brewing accessories.

- Keg couplers can be sourced from reputable suppliers for reliability.

Overview to Draft Beer Systems

The craft beer movement has transformed home brewing. Devotees adopting unique brews have increased the need for custom draft beer systems. These configurations are vital for preserving the beer’s taste and integrity intact. They are critical for those passionately involved in their brewing projects.

The Rise of Craft Beer in Home Brewing

In recent years, craft beer has soared in favor across the United States. This surge is propelled by local brewers’ cutting-edge profiles and styles. As devotees strive to emulate these sensations at home, many are adopting home brewing. With premier draft beer systems, they can attain commercial-level excellence, enhancing their home brewing projects.

Reasons to Prefer Draft Beer Over Packaged?

Draft beer systems provide benefits that bottles cannot. They are synonymous with refreshing quality and enhanced flavor. When maintained at perfect conditions, such as 38°F, and with spotless lines, these systems sustain beer excellence excellently. Regular maintenance is vital in sustaining the draft beer’s exceptional taste.

Within commercial venues, draft systems show value. Selling a 15-gallon keg, delivering approximately 124 servings, can substantially increase revenue. At $3 per pint, this translates to $372 from a single keg. This economical edge, along with serving impeccable craft beer, establishes draft systems superior over bottles.

D Type Keg Coupler Outline

Throughout North America, the D type keg coupler is crucial to drawing from kegs seamlessly. It’s specifically made for Sankey D kegs, rendering it the preferred option for brews like Budweiser, Coors Light, and Miller Lite. Understanding its architecture and its operation is critical for optimal operation, whether in business environments or for residential brewing enthusiasts.

Defining a D Type Keg Coupler?

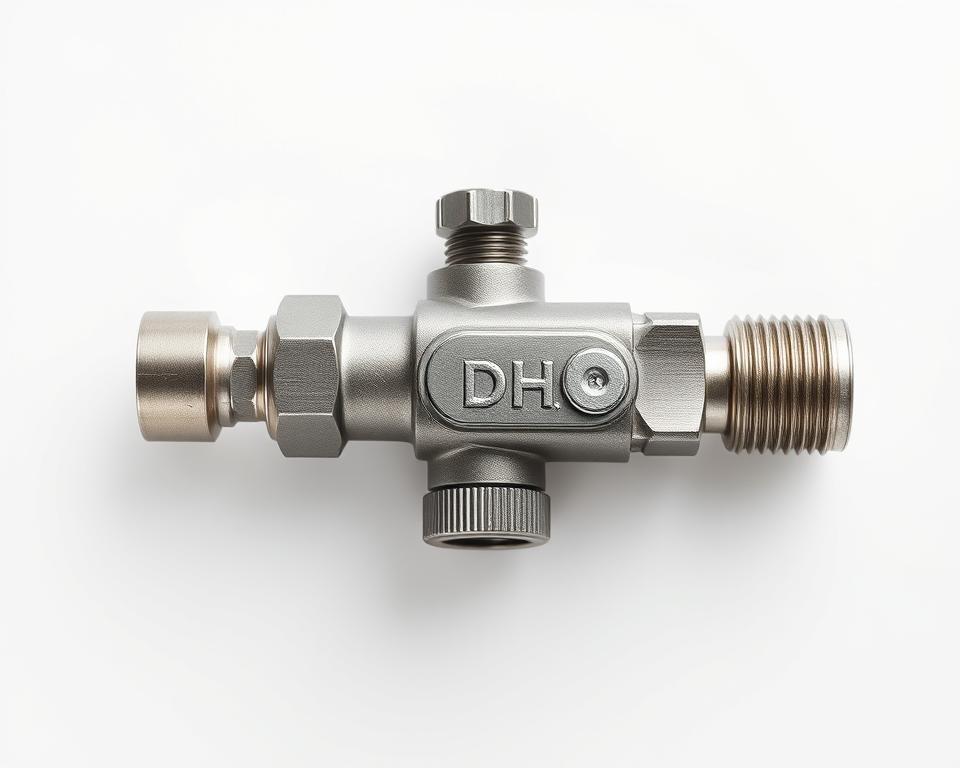

Alternatively called the American Sankey coupler, the D type connects to US Sankey faucet valves. It’s crucial in delivering a variety of North American beers. Fabricated from nickel-plated brass and a stainless steel probe, it features robustness and rust-preventive qualities. Its size, 5 inches tall and 4 inches wide, suit it well for kegs from Michelob, Busch, and Labatt.

Operation of the D Type Keg Coupler

The operation of the D type keg coupler is uncomplicated yet capable. A 5/16″ I.D. gas tube attaches to the entry, channeling CO2 into the keg. This generates the pressure required to propel beer through the system. An inbuilt safety feature stops surplus pressure, improving safety drastically. Owing to its metal wing handle, it’s more robust than variants with plastic levers, catering to both home and professional users consistently.

Picking the Appropriate D Type Keg Coupler

Choosing the proper D type keg coupler is vital for beer delivery success. It’s necessary to evaluate a number of criteria to confirm you choose wisely. The right apparatus will not only preserve your beer’s integrity intact but also ensure lasting efficiency and longevity.

Key Considerations When Choosing

When choosing a D type keg coupler, reflect on these critical points:

- Performance: It must be compatible with leading brands, including Coors and Budweiser.

- Dimensions and Clearance: Choose a compact design if you’re restricted by space.

- Ease of Use: Opt for a coupler that offers a easy-to-operate lock-down mechanism.

Compatibility with Different Keg Types

Verifying your coupler matches different keg types is crucial for best results. Typically, D type couplers are compatible with popular North American beers. Examples include Molson, Corona, and Yuengling fit this coupler. It’s also important to recognize other keg formats, like U-type or S-type, to avoid issues during dispensing.

Longevity and Material Quality

The material of your beer delivery equipment greatly influences its longevity. Stainless steel is often chosen for its rust prevention and simple maintenance. For illustration, the Taprite D Style Keg Coupler offers a durable stainless steel construction. This boosts its longevity, especially in frequent use. Moreover, availability of substitute parts can avert full complete substitutions.

Advantages of Using a D Type Keg Coupler

The D type keg coupler is helpful for professional and home brewers alike. It elevates the draft beer system, making sure beer remains high-quality. By maintaining beer quality and streamlining installation, it is a premier choice.

Preserving Beer Quality and Freshness

Notable for beer preservation, the D type keg coupler limits oxidation and maintains carbonation. This retains the beer’s freshness and taste, akin to mass-produced options. Examples include Budweiser and Corona utilize D-type couplers, demonstrating their role in flavor retention.

Easy Installation and Upkeep

The straightforwardness of setting up a D type keg coupler stands out. It offers effortless setup, suiting both experts and novices. Upkeep is equally uncomplicated, guaranteeing the system remains in prime condition effortlessly.

Enhanced Draft Performance

A D type keg coupler significantly boosts draft output. It assures an optimal pour, harmonizing foam and liquid for a better enjoyment. Its robust system provides steady beer circulation, essential for intensive environments and home pubs.

| Feature | Information |

|---|---|

| Customer Rating | 4.8 out of 5.0 based on 15 reviews |

| Top Reviews | 73% (11 out of 15) |

| Value | $39.99 |

| Shipping | Complimentary over $59 or $8.99 flat rate |

| Mass | 2 lb |

| Lifetime | Users report over 6 years with no issues |

Frequent Problems and Solutions with Keg Coupler Parts

Consistent care and quick diagnosis are crucial to steering clear of keg coupler issues that impede beer delivery. By identifying common failures, you can keep your draft systems running smoothly. This discussion offers strategies for diagnosing issues with keg coupler and advises on substituting parts efficiently.

Identifying Malfunctions in Keg Couplers

Multiple faults may affect your keg coupler, causing inferior beer dispensing. Typical problems include leaks due to insecure connections or old rubber seals, accounting for about 25% of reported malfunctions. Moreover, obstructed beer lines, often due to poor sanitation, affect roughly 15% of systems.

Opting for an unsuitable coupler type contributes to about 10% of pouring issues. A further problem is pressure relief valve failure in G-Type and U-Type couplers, which impacts around 5% of older versions. Identifying these problems early is essential to avoid more major problems. Consistent monitoring and correct use are key for ensuring efficient beer service.

Replacing Keg Coupler Components Effectively

When issues arise, knowing how to replace keg coupler parts is essential. For successful replacement, first determining the malfunctioning part, like an O-ring or check valve. Then, unscrew the coupler from the keg by twisting it anticlockwise.

Install a new part, ensuring it aligns properly and is compatible. Subsequently, reattach the coupler by applying pressure and turning the handle right to lock it in place. Always check for leaks before reconnecting the beer line, validating a tight seal.

Proper diagnosis of keg couplers not only increases your equipment’s life but also ensures the excellence of beer dispensed. Following a regular maintenance routine can greatly reduce the chances of failures, thereby boosting the beer service.

Conclusion

The D type keg coupler guide is vital for home brewers and bar owners aiming to improve their draft beer systems. It aids users in selecting the proper gear, making sure the production of top-quality, tasty beer. D type couplers are widely used throughout North America, making them key for working with major American beer labels such as Budweiser and Miller.

Caring for keg couplers is vital for delivering fresh, delicious beer. This is crucial in both business and home brewing contexts. Consistent cleaning stops contamination and is critical for client approval in eateries and pubs. Home brewers will find that understanding maintenance protocols significantly improves their brewing process.

Securing high-quality brewing equipment is essential for superior beer dispensing. Installation Parts Supply is a renowned supplier for D type keg couplers and maintenance accessories. By opting for the proper gear and embracing proper maintenance, brewers can significantly improve their beer delivery experience. Each pour becomes a better and successful session, elevating the brewing journey.

Frequently Asked Questions

What range of keg couplers are available?

There are multiple keg couplers, such as the D type (Sankey D), prevalent for American kegs. Other variants include the S, G, and A systems. Each is tailored for specific keg styles.

What is the correct way to install a D type keg coupler?

For installing a D type keg coupler, primarily confirm it’s spotless and intact. Position it over the keg’s mouth, push down, and twist clockwise until tightly fastened. Then, connect the gas and beer lines, verifying that all junctions are tight.

What maintenance do keg couplers require?

Keg coupler upkeep entails washing after every use and checking for seepage. Also, promptly swap out damaged parts. Always opt for reliable suppliers for keg coupler parts to preserve functionality.

How does the D type keg coupler benefit draft beer systems?

The D type keg coupler is key for joining gas and beer lines to a keg. This connection is important for dispensing draft beer at its peak quality, with ideal carbonation and freshness.

Where can I purchase a D type keg coupler?

D type keg couplers are sold from various providers, including Installation Parts Supply. They offer a wide selection, ensuring you find the perfect coupler for your demands.

How can I troubleshoot issues with my keg coupler?

If experiencing issues, initially ensure all joints are tight. For leaks or inadequate operation, inspect the coupler for damage. Substituting malfunctioning parts often fixes these problems.

From what material are D type keg couplers constructed?

D type keg couplers are mostly crafted from stainless steel. This alloy offers durability, longevity, and resistance against corrosion, shielding your beer dispensing system from contamination.

Is a D type keg coupler compatible with other keg types?

No, a D type keg coupler is solely for Sankey D kegs. Attempting to use it with varied keg types can lead to poor connections and likely leaks.