Endoscopy by AMT in Singapore: Expert Care.

Now, over 40% of advanced endoscopic devices in Southeast Asia have precision parts from Metal Injection Molding. This boosts safe, speedy procedures across the area.

Here’s how AMT in Singapore leads endoscopy with a blend of clinical expertise and high-tech manufacturing. They use Metal Injection Molding (MIM), assemble in a 100K cleanroom, and use ETO sterilization. This all helps in making single-use devices and sterile packaging for AMT – endoscopy.

Endoscopy centers in Singapore are seeing significant benefits. Improved imaging, miniaturized optics, and strong training programs lead the way. For patients, that means minimally invasive diagnostics and therapies, shorter sedation times, and faster recovery.

AMT’s contributions also address broader challenges such as cost pressures, specialist availability, and regulatory compliance region-wide. This article outlines how AMT’s endoscopy capabilities support clinicians and patients alike. It focuses on better access, safety, and saving money.

Primary Highlights

- AMT endoscopy integrates MIM, 100K cleanroom assembly, and ETO sterilization to deliver reliable components.

- AMT-enabled devices support HD, minimally invasive procedures that improve patient recovery.

- Singapore endoscopy centers leverage AMT’s parts to strengthen clinical workflows and device safety.

- Advanced systems reduce sedation needs and enable combined diagnostic/therapeutic sessions.

- Costs, specialist training, and regulation influence access to AMT-enabled endoscopy services in the region.

Endoscopy Explained and AMT’s Contribution

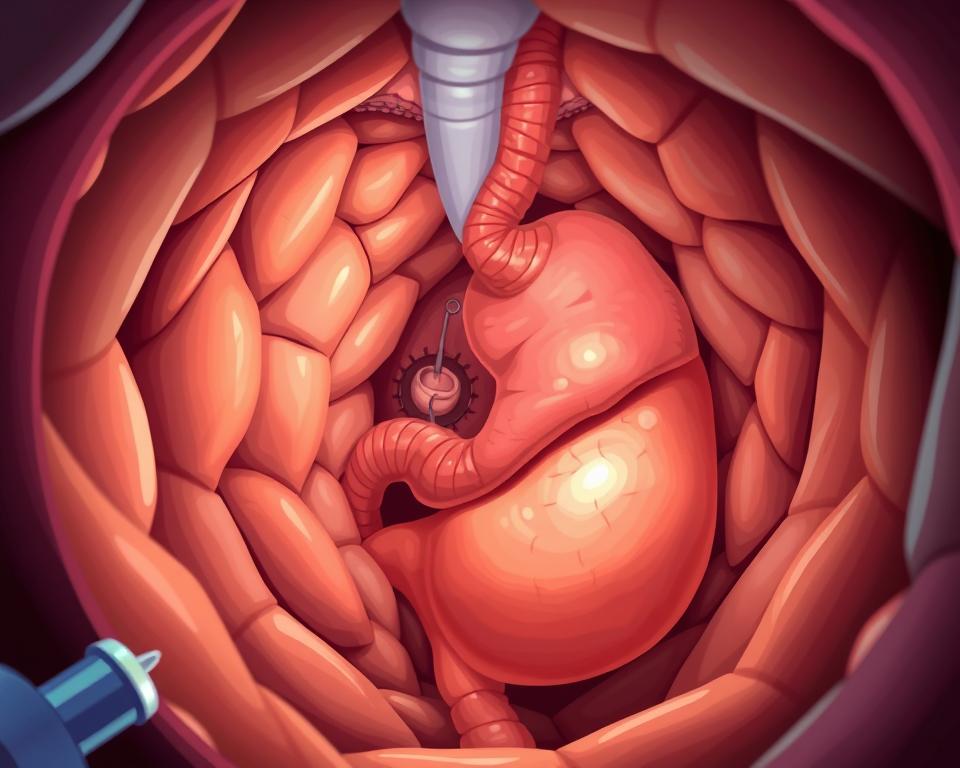

Endoscopy lets doctors view internal anatomy without large incisions. It uses small cameras on flexible or rigid scopes. This approach enables visualization, diagnosis, and treatment in a single session. Recovery time is shorter and open surgery is often avoided.

What Endoscopy Does

Endoscopy evaluates regions such as the GI tract, airways, and urinary system. They can take samples, remove growths, and do treatments with little cuts. This means patients don’t need heavy sedation, can leave the hospital sooner, and get back to life quicker.

How AMT Advances Endoscopy with Technology

AMT manufactures precision parts that enhance endoscope performance. They use a special molding method and clean assembly to meet strict standards. Their parts, like biopsy tools and electrodes, come ready for doctors to use. This supports faster workflows and safer patient care.

Endoscope Evolution to HD & Mini Scales

Early endoscopes of the 19th century were basic tubular devices. Today’s systems use mini digital cameras and highly flexible scopes. Enhanced imaging and lighting improve visualization and diagnosis. Early-stage AI assists with faster lesion detection.

Thanks to companies like AMT, these tools are getting even better. They help doctors in Singapore do more complex treatments with less risk. Patients receive high-quality care without extensive surgery.

AMT Endoscopy Solutions

AMT serves as an all-in-one partner for device makers and hospitals in Singapore. They blend fine manufacturing, cleanroom assembly, and sterilization for use-ready tools that match clinical timelines. This accelerates development from rapid prototypes to full-scale production while maintaining regulatory focus.

What AMT Delivers for Endoscopy

AMT’s endoscopy solutions include Metal Injection Molding (MIM), finding precision components, assembly in a 100K cleanroom, and ETO sterilization. The company aids in producing single-use devices, sterile packaging that peels open, and sterilization after manufacturing so instruments can go straight to the operating room. Manufacturers see shorter lead times and clinicians receive sterile, ready-to-use tools immediately.

How AMT integrates manufacturing (MIM) and device design

MIM creates complex geometries and micro-features that are hard to achieve otherwise. AMT combines MIM with design focused on manufacturing to cut down on the number of parts by merging several into one. Results include tight precision at micro-scales, improved reliability, and reduced assembly time.

Examples of AMT-supplied endoscopic parts

AMT supplies biopsy forceps and graspers for GI/urology, clamps and scissors for delicate handling, and precision biopsy needles. They also offer single-use TURP bipolar electrodes in stainless steel or tungsten alloy, all sterile in packages that peel open. Each item is made with consistent quality and assembled in clean conditions to ensure they’re safe for clinical use.

| Component | Manufacturing Method | Typical Materials | Clinical Use |

|---|---|---|---|

| Biopsy forceps (GI/Uro) | MIM plus secondary finishing | Stainless steel 316L | Tissue sampling in GI and urology |

| Graspers | MIM precision forming | Stainless steel, tungsten alloys | Tissue handling and retrieval |

| Bipolar TURP electrodes | MIM plus post-machining | Tungsten alloy, stainless steel | Bipolar resection (urology) |

| Clamps & scissors | MIM and micro-machining | Medical-grade stainless | MI instrument tips |

| Biopsy needles | MIM and heat treatment | Stainless steel | Targeted tissue extraction with precise geometry |

With AMT’s endoscopy solutions, the number of assembly steps drops and consistency in each batch goes up. Doctors get devices that are clean, packaged, and ready for surgery. And manufacturers can produce a large amount efficiently and affordably.

Advanced Techniques in Singapore

Singapore offers a broad spectrum of advanced endoscopy methods. These are for diagnosis and treatment. Top hospitals and centers run advanced endoscopy suites. They deploy the latest tools for simple and complex cases alike.

GI Capabilities in Endoscopy

Gastrointestinal endoscopy includes procedures like esophagogastroduodenoscopy and colonoscopy. They offer direct viewing, targeted biopsy, polypectomy, and control of bleeding in one session. Techniques like endoscopic mucosal resection and submucosal dissection can treat early cancers. And they do this without the need for open surgery.

Minimally invasive endoscopy approaches and patient recovery benefits

Minimally invasive endoscopy uses flexible scopes, tiny cameras, and tools for treatment. These advances lessen tissue damage and reduce the need for sedation. As a result, hospital stays shorten. Patients resume normal activities sooner and face fewer complications than with open surgery.

Therapeutic endoscopy that combines diagnosis and treatment in one procedure

Many endoscopic procedures offer both diagnosis and treatment in a single session. This enables doctors to find and remove polyps, take tissue samples, and perform coagulation or resection all at once. This reduces repeat anesthesia, shortens hospital time, and enables outpatient/day-surgery care.

AMT-enabled tools and precision parts enhance advanced endoscopy in Singapore. Innovations support higher accuracy and safer complex procedures. Consequently, regional patients access more up-to-date care.

AMT Endoscopy Technology & Instrumentation

AMT delivers clinical-grade innovations for endoscopy. They bring together optics, precise metals, and disposable items. This helps doctors see clearer and work safer during procedures.

Imaging and Illumination Advances

Surgeons get clear, live imagery with high-definition and mini cameras. LED and fiberoptic lighting enhance color fidelity and detail. This helps spot issues faster, making surgeries shorter and safer.

MIM’s Role in Precision Components

MIM enables precise metal components for endoscopy. Biopsy forceps, grasper jaws, and electrode tips are made durable and fit well. Part consolidation reduces assembly steps and boosts reliability.

Single-Use Instruments & Sterile Packaging

Single-use tools arrive sterile to lower infection risk. AMT ensures safety with ETO sterilization and clean assembly. Sterile packaging and detailed tracking make clinical processes secure.

| Feature | Clinical Benefit | AMT capability |

|---|---|---|

| HD imaging | Improved lesion detection and treatment precision | Integrated CMOS + LED/fiber lighting |

| MIM precision parts | Precision, strength, and consolidation | Metal Injection Molding for forceps, electrodes, micro-instruments |

| Sterile single-use instruments | Reduced infection risk, simplified reprocessing | Peel packs, ETO, cleanroom assembly |

| Traceability and packaging | Compliance and supply confidence | Lot traceability, sterile barrier systems, validated processes |

AMT unites imaging, MIM components, and single-use tools for modern practice needs. Focus areas are accuracy, reliability, and safety in Singapore and beyond.

Singapore Endoscopy Care

In Singapore, hospitals and special clinics have a strong network for endoscopy services. Expert teams—gastroenterologists, nurses, and techs—use advanced equipment to manage care efficiently. High-quality devices ensure safety for both local and visiting patients.

Workflow Support from AMT

AMT precision parts reduce failures and keep schedules on time. Exacting instruments (e.g., biopsy forceps) improve case turnover. Reliable quality smooths procedures and reduces delays.

Comfort & Faster Recovery

Today’s endoscopy equipment is more advanced, using thinner scopes for comfort. These improvements mean many patients only need mild sedation. Result: less tissue trauma and faster discharge.

Sterilization & Cleanroom Integration

AMT aligns with Singapore’s hospital sterilization methods, using cleanrooms and ETO sterilization. Single-use options reduce reprocessing workload and infection risk. This approach ensures equipment is safe and ready for patients.

Operational efficiencies and service ecosystem

Disposables accelerate turnover and free staff for clinical tasks. With a reliable flow of AMT parts, high-demand services run smoothly. This collaboration supports consistent, high-quality care.

| Operational Need | AMT Contribution | Benefit for Patient Care |

|---|---|---|

| Instrument reliability | Precision MIM components for forceps and graspers | Fewer delays, safer outcomes |

| Faster turnover | Single-use devices and stocked sterile kits | Faster patient throughput and reduced wait times |

| Assured sterility | 100K cleanroom + ETO | Lower infection risk, compliant flow |

| Patient comfort | Mini scopes, refined accessories | Less sedation/discomfort, quicker recovery |

Training and Competency

To work with modern endoscopy tools, you need both education and hands-on experience. GI, urology, and surgical specialists complete focused training. Simulation and supervised cases reinforce competency. This way, they learn to safely use the latest technology.

Training to Operate Advanced Systems

Endoscopy training emphasizes procedure volume and competency assessment. Learners work with top-notch cameras, cutting devices, and learn to manage the equipment. Education covers component selection and safe disposable use. This reduces equipment-related errors. The training often includes tests and monitored cases.

Expertise Concentration & Access

In Singapore, top-end endoscopy training is mainly at big hospitals. These places become experts because they handle many cases. However, distant patients may face access barriers. Health systems have to think about whether to spread out resources or keep them centralized.

Continuous education and competency for therapeutic care

Teams must keep pace with new tools and computer-aided imaging. They often check their work and learn from mistakes to stay safe. Companies like AMT offer courses to help doctors understand the technology better. Keeping up with training means fewer problems and happier patients.

Resourcing and Cost

Keeping a team skilled involves spending on training and time for teaching. These costs influence treatment pricing. Planning how to grow the workforce ensures that more people can get advanced endoscopy as needed.

Clinical Uses of Endoscopy

Endoscopy spans broad diagnostic and therapeutic indications. In Singapore, doctors use these methods for many purposes. They check symptoms, handle benign (non-cancerous) problems, and take tissue samples with little trouble for the patient.

Common gastrointestinal procedures

Doctors use diagnostic upper endoscopy and colonoscopy to find bleeding sources, look into indigestion issues, and help with checking for colorectal cancer. They also remove polyps, cut out bad tissue, stop bleeding, and take targeted samples. AMT-supplied tools enable precise sampling for early cancer detection.

Urology Use Cases

Ureteroscopy/cystoscopy visualize the urinary tract for stones, obstruction, and tumors. For BPH, transurethral resection is common. TURP electrodes are precisely manufactured. They come with tips made of stainless steel or tungsten for cutting and stopping bleeding.

When minimally invasive endoscopy is preferred

MI endoscopy is preferred for early tumors, benign obstruction, and urgent bleeding. It’s also good for cases where it’s safer to sample in a less invasive way than with open surgery. People with other health problems also get better faster and need less time under anesthesia with this method.

Decision factors

Choosing between endoscopic procedures and open surgery depends on the health issue, size and location of the lesion. The choice also relies on the available skills and tools. Patient preference and expected recovery time are important considerations.

| Indication | Common Endoscopic Approach | AMT Component Role |

|---|---|---|

| UGI bleeding | UGI endoscopy + hemostasis | High-definition optics and biopsy forceps for targeted sampling and coagulation |

| Colorectal polyp | Colonoscopy with polypectomy or EMR | Miniaturized graspers and snares produced via precise MIM processes |

| Suspected bladder tumor | Directed biopsy via cystoscopy | Durable single-use biopsy instruments and endoscopic cameras |

| BPH | Bipolar TURP resection | Single-use TURP electrodes (stainless/tungsten) for resection/coagulation |

| Stone (ureteral) | URS + laser lithotripsy | Precision tips and miniaturized instrument shafts for scope passage and stone manipulation |

Regulatory and Sterility Considerations

Patient safety depends on meticulous cleaning, assembly, sterilization, and documentation. AMT uses advanced 100K cleanroom assembly lines. These lines combine top-notch assembly methods with reliable sterilization processes. This supports infection prevention and meets hospital standards.

Cleanroom Assembly at AMT process concludes with sterile, ready-to-use devices. For reusable tools, AMT provides validated cleaning/sterilization guidance. They also explain which sterilization methods work best. ETO sterilization is key for items sensitive to heat, ensuring safety and supporting audits.

Choosing between single-use and reusable instruments involves multiple factors. Single-use instruments reduce infection risks and make meeting regulations easier. On the other hand, reusable devices can save money but require a strong system for cleaning and sterilization to stay safe.

In Singapore, medical devices must meet certain standards. Firms register with the HSA and adhere to ISO 13485. Their electronic parts need to meet certain IEC standards. Also, providing clinical evidence and conducting post-market surveillance are crucial for keeping up with regulations.

Medical tourism brings extra challenges. Hospitals catering to international patients need detailed records of where their devices come from, their sterilization history, and staff training. This documentation meets foreign insurance/accreditation standards. It supports informed choices and a sterile, traceable supply chain.

| Aspect | Single-use | Reusable |

|---|---|---|

| Infection risk | Low; one-and-done use lowers cross-contamination | Depends on validated reprocessing + tracking |

| Cost profile | Higher per-case consumable cost; lower capital needs | Higher capital; lower consumables per case over time |

| Sterilization | Delivered sterile after ETO sterilization or aseptic packaging | Requires autoclave, ETO sterilization, or validated cycles per material |

| Regulatory & documentation | Simpler traceability for single lots; packaged sterile barrier records | Comprehensive reprocessing logs, maintenance, and performance validation |

| Environment | More waste volume; recycling programs emerging | Less disposable waste; energy/water use for reprocessing |

| Operations | Reduces reprocessing workload; faster turnover between cases | Requires sterilization staff, validated SOPs, and downtime for processing |

Hospitals need to consider risks, costs, and rules when picking endoscopy solutions. Accurate records, proper ETO, and clean assembly are crucial. These ensure safety and support regulatory adherence.

Economics & Access in Singapore

Advanced endoscopy clearly benefits patients. High-definition equipment and special tools make costs go up. These costs affect how much hospitals charge for procedures and how providers set up their services.

Endoscopy suites with the latest tech can be very expensive. Ongoing maintenance adds yearly operating expense. Disposables and continuous training further increase expense. Collectively, these factors shape overall service cost.

Medical tourism and regional demand

Singapore’s hospitals draw patients from all over Southeast Asia. Patients seek complex procedures unavailable locally. Shorter wait times and high-quality service are big draws. Partnerships help keep costs down and service consistent for visitors.

Maintenance, lifecycle, and unit economics

Hospitals have to think about the upfront costs and the costs over time. Recurring consumables and parts add up. Smart contracting and inventory control can reduce strain. Clear accounting helps compare costs between different centers more easily.

Equity and two-tier access risks

Concentrating advanced care in a few centers can widen gaps. Access hinges on funding and insurance. If unmanaged, benefits skew to wealthier patients. Planning should aim to spread care evenly to all who need it.

Policy levers and collaboration

Public–private collaboration can keep care innovative and affordable. Steps like subsidies and clearer pricing help ease financial pressures. Safe disposable strategies can reduce infection risk without undue cost. These efforts help more people get the care they need fairly.

| Factor | Impact on Pricing | Potential Policy Response |

|---|---|---|

| Capital equipment | High capex raises per-case amortization | Subsidies, leasing options, shared suites in public hospitals |

| Maintenance/software | Annual contracts add predictable operating expenses | Competitive tenders, multi-year agreements |

| Consumables/single-use | Direct per-case cost increase | Evidence-based use, reimbursement tuning |

| Specialist training and staffing | Higher labor and credentialing costs | Gov-funded training, regional centers |

| Medical tourism demand | Revenue can help subsidize advanced services | Quality accreditation, transparent pricing for international patients |

| Supply-chain integration | Improved availability can lower amt endoscopy cost | Local manufacturing incentives, partnerships with AMT |

| Insurance and subsidy models | Sets out-of-pocket burden | Expanded coverage for priority procedures, means-tested subsidies |

Future Trends: AI, Telehealth, Manufacturing

Innovation is changing the way endoscopic care is given in Singapore and nearby areas. New technologies in imaging, connecting remotely, and making things are coming together. The result: expanded capabilities, easier workflows, and lower per-procedure cost. These changes affect doctors, companies making devices, and hospitals.

AI-Assisted Detection & Support

Machine learning now helps doctors spot small lesions and figure out what kind of polyps are there during checks. AI support enhances accuracy and reduces misses. This gives doctors an extra pair of eyes while working.

Deploying AI requires validation, clear performance metrics, and bias mitigation. Staff at hospitals need to learn how to understand what AI says and balance it with their medical knowledge.

Telehealth Devices & Remote Management

Telehealth enables remote oversight and consultation. Remote experts can observe live, advise on biopsies, and offer second opinions.

Managing devices from a distance means less need for in-person tweaks and using less protective gear. Teams monitor health, schedule maintenance, and update systems proactively.

Scaling Precision with MIM

MIM lowers the cost of producing small, precise parts for modern scopes/tools. Metal injection molding combines steps, reduces assembly time, and increases the amount made while keeping quality high.

Quicker prototype making and lower costs per item help in improving new designs. Better part consistency boosts how long devices last and lets clinics use new tools with a steady supply.

Practical Implications

AI, telehealth, and MIM improvements enable distributed care and faster diagnosis. Health systems need to update training, spend on cybersecurity, and have clear rules for data.

Device makers should collaborate closely with clinicians. They should validate usability and integrate AI/remote support smoothly into workflows.

| Trend | Key Benefit | Primary Challenge |

|---|---|---|

| AI-assisted detection | Better detection and standardized interpretation | Validation, bias mitigation, clinical governance |

| Telehealth endoscopy | Remote expertise and centralized oversight | Bandwidth, privacy, workflow integration |

| MIM precision | Scalable precise parts at lower unit cost | Tooling, QC, and traceability requirements |

| amt endoscopy solutions | End-to-end continuity of device supply | Interoperability, training, maintenance models |

The Bottom Line

AMT endoscopy in Singapore pairs precision manufacturing with cleanroom assembly. This approach supports high-quality care that’s less invasive. Solutions include clear imaging, dependable single-use tools, and durable components.

The perks include better diagnosis with HD images and AI. Procedural workflows are more streamlined. This yields major improvements for endoscopy departments.

However, challenges include equipment and training costs. Strict regulatory compliance is also required. Choosing reusable vs single-use affects infection control and cost. Addressing these ensures broader, equitable access.

Going forward, integrating AI, telehealth, and advanced manufacturing will enhance services. In Singapore, manufacturers, providers, and policymakers must collaborate. The shared goal is safe, affordable, widely available endoscopy care.